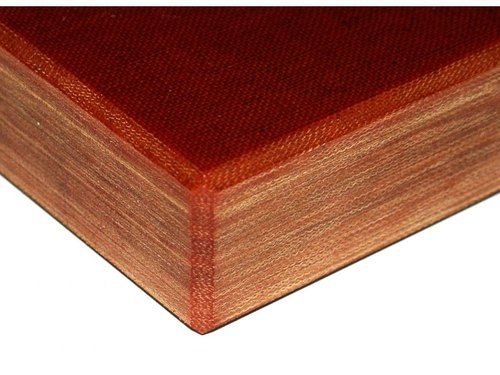

Canvas Phenolic Sheets

Product Details:

- Type Canvas Phenolic Sheet

- Material Phenolic Resin Reinforced with Canvas Cloth

- Transparency Opaque

- Hardness 65-85 Shore D

- Thickness 1 mm to 50 mm

- Size 1220 mm x 2440 mm (standard), custom sizes available

- Weight Approx. 1.4 g/cm

- Click to view more

Canvas Phenolic Sheets Price And Quantity

- 1000 Piece

- 280 INR/Kilograms

Canvas Phenolic Sheets Product Specifications

- 65-85 Shore D

- Canvas Phenolic Sheet

- Brown

- Approx. 1.4 g/cm

- 1 mm to 50 mm

- Opaque

- Phenolic Resin Reinforced with Canvas Cloth

- 1220 mm x 2440 mm (standard), custom sizes available

Canvas Phenolic Sheets Trade Information

- 500 Piece Per Day

- 1 Days

- Yes

- Contact us for information regarding our sample policy

- Wooden Crate or HDPE Packing

- Middle East, Africa, Asia

- All India

Product Description

Phenolic Cotton Cloth Laminated Sheets

Electrotechnical sheet textolite or Phenolic Cotton Cloth Laminated Sheets is a laminated material made by hot pressing of cotton cloths impregnated with a thermosetting phenolformaldehydebased binder

Due to the use of cotton cloths the phenolic cotton cloth mixture has high compression strength and increased resilience favorably lends itself to machining by drilling cutting and forging That is why the phenolic epoxy resin cotton cloth laminated sheets are widely used to make parts loaded with reversed electrical and mechanical stresses or working under friction bushings cams etc

The textolite or phenolic cotton cloth sheets are used as insulating material for work in transformer oil and in the air at a normal relative humidity of the environment and at 50 Hz of frequency

Longterm allowable working temperature 65C to 105

Phenolic cotton cloth sheets benefits

very good mechanic and thermal properties

lasting operating temperature to 120C

approved for oil and air

low friction coefficient

high creep resistance

vibration absorption properties

easy mechanical processing

electroinsulation properties

Types of phenolic epoxy cotton cloth textolite sheets

Phenolic cotton cloth sheets type A has improved electrical properties and is mostly used as insulating material

Phenolic cotton cloth sheets type B same as type A but it has improved mechanical properties and is mostly used as a construction material

Exceptional Mechanical and Electrical Performance

Canvas Phenolic Sheets deliver outstanding flexural, tensile, and compressive strengths, ensuring structural integrity in demanding environments. Their excellent dielectric properties make them perfect for electrical insulation applications, safeguarding equipment and personnel from electrical hazards in various industrial and mechanical settings.

Superior Machinability and Versatility in Application

With a hardness rating of 65-85 Shore D and a smooth, semi-matte finish, Canvas Phenolic Sheets can be easily cut, drilled, and machined to precise requirements. Their adaptability makes them a popular choice for components like gears, bushings, panel insulation, and more across multiple industries.

FAQ's of Canvas Phenolic Sheets:

Q: How should Canvas Phenolic Sheets be processed for mechanical or electrical components?

A: Canvas Phenolic Sheets are simple to machine using standard cutting, drilling, and shaping tools. Their excellent machinability allows customization to required dimensions and shapes, making them suitable for gears, bushings, and insulation panels.Q: What makes Canvas Phenolic Sheets ideal for electrical insulation applications?

A: These sheets possess excellent dielectric properties, ensuring safe and effective insulation in high-voltage environments. Additionally, their low water absorption and self-extinguishing flame resistance further enhance their reliability and safety in electrical systems.Q: When should I choose Canvas Phenolic Sheets over other insulating materials?

A: Choose Canvas Phenolic Sheets when your application requires outstanding mechanical strength, high temperature resistance (up to 120C), superior dielectric performance, and flame resistance. They are particularly suited for industrial, electrical, and mechanical components that demand long-term durability.Q: Where can Canvas Phenolic Sheets be used most effectively?

A: These sheets excel in environments needing mechanical precision and excellent insulation, such as electrical switchgear, transformer insulation, machinery gears, bushings, and structural panels in control apparatus.Q: What are the benefits of using Canvas Phenolic Sheets in engineering and electronics?

A: The benefits include high flexural and compressive strengths, excellent machinability, reliable flame resistance, and stable insulation properties, which collectively enable long-lasting, high-performance mechanical and electrical parts.Q: How does water absorption affect the performance of Canvas Phenolic Sheets?

A: With a water absorption rate of less than 1.5%, these sheets maintain their structural and insulating properties even in humid environments, ensuring consistent performance and dimensional stability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Phenolic Sheets' category